In today’s fast-paced supply chain environment, efficiency and space optimization are vital to the success of any warehouse. Businesses are continuously searching for storage solutions that not only improve space utilization but also enhance picking speed and inventory rotation. Among the most innovative systems gaining recognition is pallet live racking. This dynamic storage solution offers unique benefits, particularly for industries that rely heavily on first-in, first-out (FIFO) stock management.

As warehousing evolves with automation, sustainability, and smart technologies, pallet live racking is positioned to play an even more significant role in the future of logistics.

Understanding Pallet Live Racking

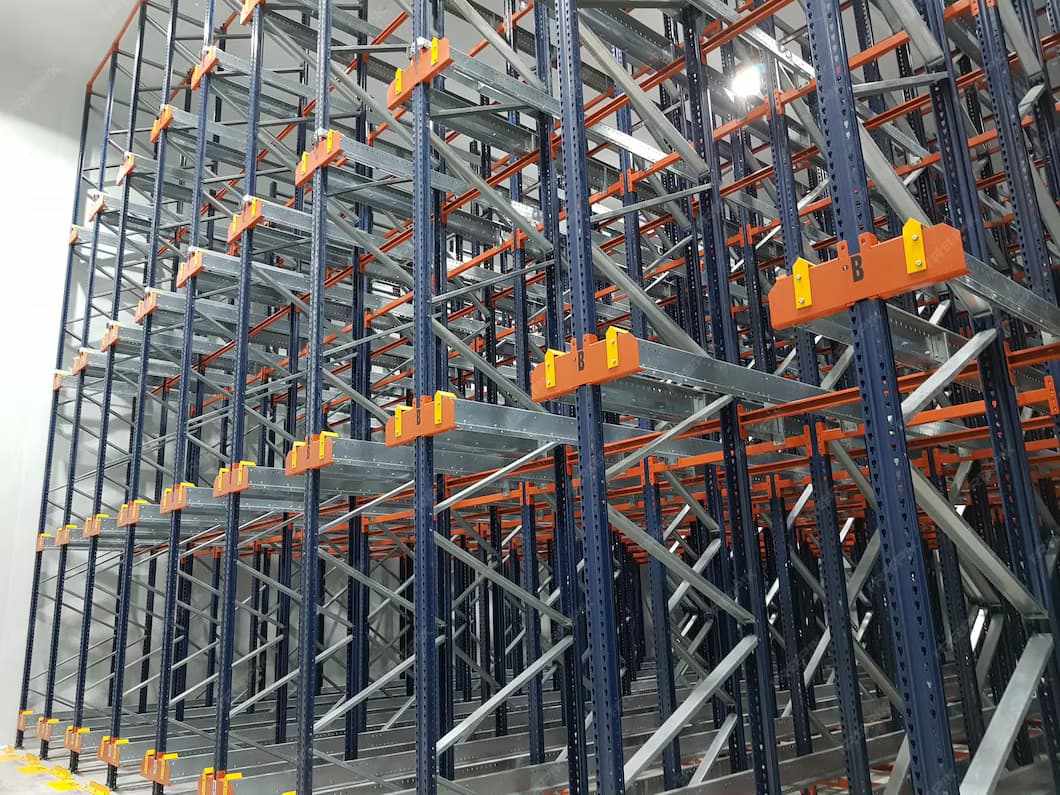

Pallet live racking is a gravity-fed storage system designed to maximize storage density while ensuring smooth product rotation. Pallets are loaded at the higher end of inclined roller lanes and move forward automatically by gravity toward the picking face. Once the first pallet is retrieved, the next pallet advances into position, allowing for continuous stock flow.

Key Features of Pallet Live Racking

Inclined roller lanes that guide pallet movement.

FIFO stock management ensuring older stock is used first.

High-density storage capacity compared to standard racking.

Reduced travel time for forklift operators.

This system is particularly suited for industries such as food and beverage, pharmaceuticals, and FMCG sectors, where expiry dates and stock freshness are critical.

Benefits of Pallet Live Racking in Modern Warehousing

Maximizing Space Utilization

One of the primary advantages of pallet live racking is its ability to optimize warehouse space. By eliminating aisles between every row, it allows for a higher concentration of pallets in a given area, improving storage density significantly.

Improved Inventory Rotation

For businesses that prioritize FIFO stock management, pallet live racking is ideal. It ensures that older stock is always accessed first, reducing the risk of product obsolescence and waste.

Increased Picking Efficiency

Since pallets automatically move to the picking face, operators spend less time retrieving stock. This streamlining reduces handling time and improves overall warehouse productivity.

Enhanced Safety

The system minimizes forklift travel within storage lanes, reducing the likelihood of collisions and accidents. The controlled movement of pallets also reduces risks associated with manual handling.

The Role of Technology in the Future of Pallet Live Racking

Integration with Automated Guided Vehicles (AGVs)

As warehouses adopt robotics and AGVs, pallet live racking can seamlessly integrate with these technologies. Automated vehicles can efficiently load and unload pallets from racking systems, reducing reliance on manual labor.

Smart Sensors and IoT Connectivity

In the future, pallet live racking systems are expected to incorporate smart sensors that monitor pallet movement, stock levels, and system performance. Connected to warehouse management systems (WMS), this provides real-time visibility and enhances inventory control.

Energy Efficiency and Sustainability

Unlike automated storage systems that require constant energy input, pallet live racking uses gravity, making it inherently energy-efficient. Future developments may focus on eco-friendly materials and designs that further align with sustainable warehousing practices.

Challenges and Solutions for Widespread Adoption

Initial Investment Costs

Although pallet live racking provides long-term efficiency gains, the initial investment can be higher than traditional racking systems. However, the cost is offset by reduced labor expenses, better space utilization, and improved inventory management.

Suitability for Specific Stock Profiles

This system works best with high-turnover, uniform pallet loads. Warehouses dealing with irregular or low-rotation stock may face limitations. To overcome this, hybrid solutions combining pallet live racking with selective racking can provide flexibility.

Maintenance Considerations

Roller lanes and braking systems require regular inspection to ensure smooth operation. In the future, predictive maintenance technologies powered by AI may reduce downtime and extend system life.

Future Trends Shaping Pallet Live Racking

Integration with Warehouse Automation

The combination of pallet live racking with automated picking and retrieval systems will create highly efficient, semi-autonomous warehouses. This hybrid approach balances density with speed, ideal for large-scale distribution centers.

Data-Driven Warehouse Management

As big data and analytics continue to transform logistics, pallet live racking will play a role in providing actionable insights. Real-time tracking of stock movement will help businesses refine inventory strategies and reduce errors.

Customization and Modular Designs

The future will see more modular and customizable pallet live racking systems that adapt to the unique needs of warehouses. Adjustable roller beds, variable lane depths, and compatibility with different pallet types will enhance flexibility.

Why Pallet Live Racking Will Remain Relevant

In a competitive global supply chain, storage systems must evolve to meet increasing demands for speed, accuracy, and efficiency. Pallet live racking meets these needs by combining high-density storage with FIFO inventory management, making it indispensable for industries that handle perishable or fast-moving goods.

Its adaptability to modern technologies such as automation, sensors, and AI ensures that pallet live racking will remain a cornerstone of warehouse design for decades to come.

Conclusion

The future of pallet live racking lies in its ability to merge traditional efficiency with modern technology. By offering high-density storage, streamlined stock rotation, and compatibility with automation, it is set to become an integral part of modern warehousing strategies. Businesses that adopt this solution now will position themselves strongly for the future of logistics and supply chain management.

For organizations seeking expert solutions in pallet live racking, Dalvie Systems provides the knowledge and support required to design and implement advanced warehouse storage systems. With a focus on efficiency and innovation, Dalvie Systems helps businesses optimize their operations for long-term success.

Write a comment ...