In the fast paced environment of modern warehouses, the efficiency, safety, and organisation of storage systems are critical to operational success. Pallet racking installation plays a central role in achieving these goals, providing structured and safe storage for palletised goods. However, installing a pallet racking system goes beyond simply assembling components. Compliance with industry standards, regulations, and best practices is essential to ensure safety, durability, and operational efficiency. Non-compliance can lead to accidents, costly downtime, and legal repercussions, making adherence to standards a priority for any warehouse operation.

Understanding Pallet Racking Installation

What Pallet Racking Installation Involves

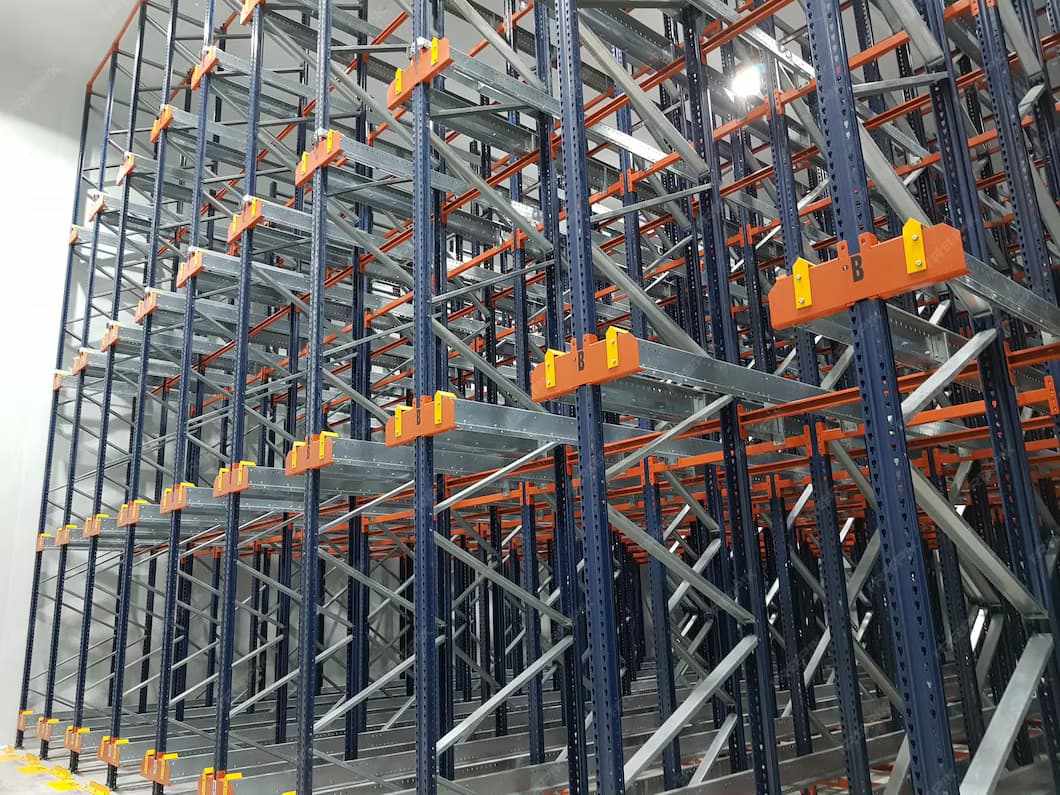

Pallet racking installation is the process of assembling and securing a storage system designed to hold palletised goods safely. The process includes positioning frames, beams, decking, and safety accessories, ensuring structural integrity, and verifying load capacity. Proper installation ensures that the system can handle operational demands while maintaining safety for employees and inventory.

The Role of Compliance in Installation

Compliance refers to adhering to legal, regulatory, and industry standards during the design, installation, and maintenance of pallet racking systems. This includes local building codes, health and safety regulations, and racking standards set by recognised authorities. Compliance ensures that the racking system meets minimum safety requirements, provides durability, and minimises risk to personnel and property.

Key Compliance Standards in Pallet Racking

Building and Structural Regulations

Pallet racking must comply with building and structural regulations that govern load-bearing capacity, stability, and construction materials. These regulations ensure that the system can safely support the weight of stored goods and withstand environmental factors such as vibrations, temperature changes, and accidental impacts.

Health and Safety Requirements

Workplace health and safety regulations govern how racking systems are installed and maintained. Compliance ensures safe access to stored goods, proper aisle widths, secure installation of beams and frames, and the use of safety accessories such as guardrails, netting, and column protectors. Adhering to these regulations reduces the risk of accidents and injuries in the warehouse.

Industry-Specific Standards

Various organisations provide guidelines and best practices for pallet racking installation. Standards such as those from the Rack Manufacturers Institute or local equivalents outline design, load capacity, and inspection requirements. Following these standards ensures that the racking system is engineered and installed to professional specifications.

Benefits of Compliance in Pallet Racking Installation

Enhanced Safety

Compliance ensures that the pallet racking system is structurally sound and installed according to best practices. This reduces the risk of collapses, falling objects, and accidents, creating a safer environment for warehouse staff. Safety compliance also protects businesses from potential legal liability in case of workplace incidents.

Longevity and Durability

Correct installation following compliance standards maximises the lifespan of the pallet racking system. Properly secured frames, accurately aligned beams, and appropriate load distribution prevent structural fatigue and damage over time, reducing the need for frequent repairs or replacements.

Operational Efficiency

A compliant pallet racking system is optimised for workflow and accessibility. Properly spaced aisles, correctly installed shelving, and secure load handling facilitate faster picking, replenishment, and inventory management. Efficient operations reduce downtime and improve overall warehouse productivity.

Legal and Insurance Advantages

Compliance with regulations is often a prerequisite for insurance coverage and legal protection. Non-compliance can result in denied claims in the event of damage or injury. Adhering to installation standards protects businesses from legal disputes and ensures that insurance policies remain valid.

Steps to Ensure Compliance in Pallet Racking Installation

Site Assessment

A professional installation begins with a thorough site assessment. Evaluating floor strength, ceiling height, column positions, and operational requirements ensures that the racking system is designed to meet both structural and functional needs.

Load Calculation and Design

Compliance requires accurate load calculations. Engineers must consider the weight of pallets, frequency of use, and potential dynamic forces during handling. Correct calculations ensure that the racking system can safely accommodate the expected loads without risk of failure.

Professional Installation

Qualified installation teams follow strict procedures to assemble frames, beams, and decking accurately. Professional installers ensure that bolts, welds, and joints meet safety standards, and that the system is level and aligned correctly.

Safety Accessories and Measures

Adding compliant safety accessories is essential. Column protectors, pallet stops, safety netting, and guardrails prevent accidents and protect both inventory and personnel. Compliance ensures these measures are installed correctly and in accordance with regulations.

Regular Inspections and Maintenance

Compliance does not end after installation. Regular inspections and maintenance are critical to ensure continued adherence to safety standards. Inspections check for damaged beams, leaning frames, or overloaded sections, allowing timely corrective action. Maintenance extends the life of the system and maintains operational safety.

Common Compliance Challenges

Overloading

One of the most frequent compliance issues is exceeding the specified load capacity. Overloading can compromise structural integrity, leading to accidents and damage. Proper training and clear load signage help prevent overloading.

Incorrect Installation

Improper assembly of beams, frames, or decking is a major compliance risk. Professional installation and adherence to manufacturer instructions ensure structural stability and safety.

Neglecting Inspections

Regular inspections are often overlooked but are critical for compliance. Ignoring inspections can allow minor issues to escalate into serious hazards. Implementing scheduled inspection routines mitigates this risk.

Ignoring Regulatory Updates

Regulations and standards may evolve over time. Staying informed about changes in building codes, health and safety laws, and industry standards ensures that racking systems remain compliant throughout their lifespan.

Advantages of Working with Professionals

Expertise and Experience

Professional pallet racking installers have the technical knowledge and experience to ensure compliance with all relevant standards. Their expertise reduces the risk of errors and guarantees a safe and reliable installation.

Efficient Project Execution

Professional teams can complete installations quickly and accurately while maintaining compliance. Efficient execution minimises disruption to warehouse operations and ensures that the system is ready for use promptly.

Tailored Solutions

Professionals assess warehouse requirements and design pallet racking systems that meet operational needs while adhering to compliance standards. Customised solutions optimise space, workflow, and safety.

Ongoing Support

Many professional installers provide post-installation support, including inspections, maintenance, and advice on system modifications. Continuous support ensures that the pallet racking system remains compliant and efficient over time.

Conclusion

Compliance in pallet racking installation is not optional; it is essential for safety, operational efficiency, and long-term performance. Adhering to regulatory standards, industry guidelines, and best practices ensures a structurally sound system that protects employees, inventory, and business assets. Proper planning, professional installation, safety measures, and regular inspections are all critical components of compliant pallet racking systems. For professional, compliant, and reliable pallet racking installation services, businesses can trust Dalvie Systems to deliver high-quality solutions that maximise safety, efficiency, and warehouse performance.

Write a comment ...