Every successful warehouse or distribution centre relies on efficient storage solutions. As inventory volumes increase, businesses must find ways to maximise space, streamline operations, and maintain safety. Industrial pallet racks are among the most versatile and widely used storage systems, offering durability, scalability, and easy access to palletised goods. For buyers, understanding the types, features, and applications of these racks is essential in making an informed investment that meets both current and future storage needs.

What Are Industrial Pallet Racks

Industrial pallet racks are steel storage systems designed to hold palletised goods in an organised and space-efficient manner. They are engineered to support heavy loads while ensuring safety and accessibility. These racks can be configured in multiple ways, allowing businesses to customise their storage according to product type, warehouse layout, and operational goals.

Key Features

Heavy-duty construction for long-lasting durability

Flexible configurations for different storage needs

Optimisation of vertical and horizontal space

Designed for safety and efficiency in busy warehouse environments

Types of Industrial Pallet Racks

Selective Pallet Racks

The most common and straightforward design, selective pallet racks allow direct access to every pallet. They are ideal for businesses with varied product lines and frequent inventory turnover.

Best for: Warehouses requiring high selectivity and fast picking.

Double Deep Racks

These racks store pallets two deep, increasing storage density while reducing aisle space. However, they require special forklifts to access the back pallets.

Best for: Facilities that need higher storage density but can manage slightly reduced accessibility.

Drive In Racks

Drive in racks allow forklifts to enter the racking structure to load and retrieve pallets. They operate on a last-in, first-out basis.

Best for: Bulk storage of uniform products with low turnover rates.

Drive Through Racks

Drive through racks are similar in design to drive in but allow forklift access from both sides. This enables a first-in, first-out flow.

Best for: Perishable goods or industries requiring stock rotation.

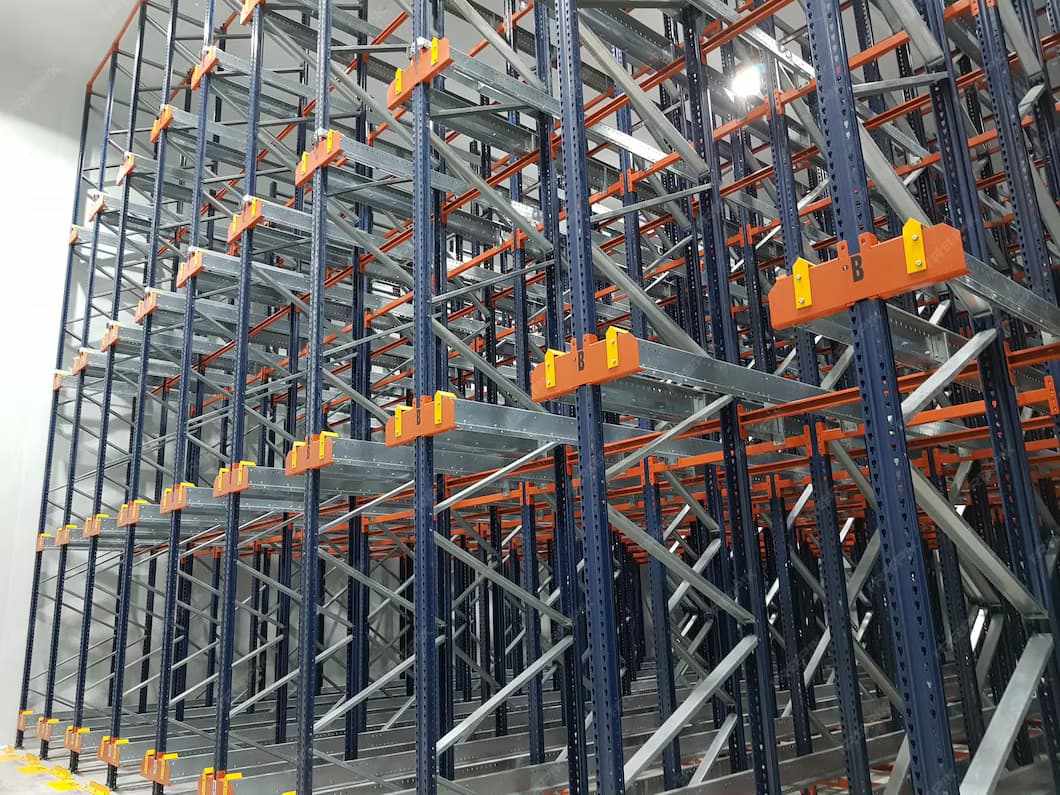

Push-Back Racks

These racks use a rail-and-cart system to store pallets on an incline. When one pallet is removed, the next slides forward automatically.

Best for: Medium-turnover products requiring both density and accessibility.

Pallet Flow Racks

Pallet flow systems use gravity rollers, moving pallets from the loading end to the picking end. This ensures first-in, first-out inventory management.

Best for: Food, beverage, and pharmaceutical industries where product rotation is critical.

Cantilever Racks

Although not designed for pallets, cantilever racks are used for storing long and bulky items such as pipes, timber, or steel beams.

Best for: Warehouses storing oversized or irregularly shaped products.

Factors to Consider When Buying Industrial Pallet Racks

Warehouse Space

Measure ceiling height, floor space, and aisle width to ensure the chosen system fits seamlessly.

Inventory Characteristics

Weight, size, and turnover rate of products should influence the choice of rack type.

Accessibility

Determine whether fast access to every pallet is essential or if high-density storage is the priority.

Safety Standards

Ensure the racks comply with relevant safety guidelines and can handle the intended load capacity.

Budget and Long-Term ROI

Balance upfront costs with the long-term efficiency gains the system will provide.

Future Scalability

Opt for modular systems that can be expanded as storage needs grow.

Advantages of Industrial Pallet Racks

Maximises warehouse storage capacity

Improves organisation and accessibility

Enhances employee productivity and workflow

Provides a safer working environment

Reduces operational costs through better efficiency

Applications Across Industries

Industrial pallet racks are used in a wide range of sectors including:

Warehousing and logistics

Food and cold storage facilities

Retail and wholesale distribution

Automotive parts and manufacturing

Pharmaceuticals and healthcare supplies

Heavy industry and construction materials

Maintenance and Safety Tips

Conduct regular inspections for damage or wear

Train staff on safe loading and unloading practices

Avoid exceeding weight limits

Install safety accessories such as rack guards and column protectors

Schedule periodic professional rack inspections

Conclusion

Investing in the right industrial pallet racks can transform warehouse efficiency, boost storage capacity, and improve overall safety. By carefully considering factors such as space, inventory, accessibility, and long-term growth, businesses can select a system that meets their unique requirements. For expert support in choosing and installing reliable pallet racking solutions, Dalvie Systems offers the knowledge and experience to deliver tailored results.

Write a comment ...