Warehouses today face growing pressure to improve efficiency, optimize space, and keep up with the demands of faster supply chains. Storage solutions play a critical role in achieving these goals, and one system that has gained popularity for its effectiveness is pallet live racking. Known for combining high-density storage with first in, first out inventory control, pallet live racking is a versatile solution that can benefit businesses across many industries.

This guide provides a comprehensive look at how pallet live racking works, the benefits it offers, its applications, and best practices for implementation.

What Is Pallet Live Racking

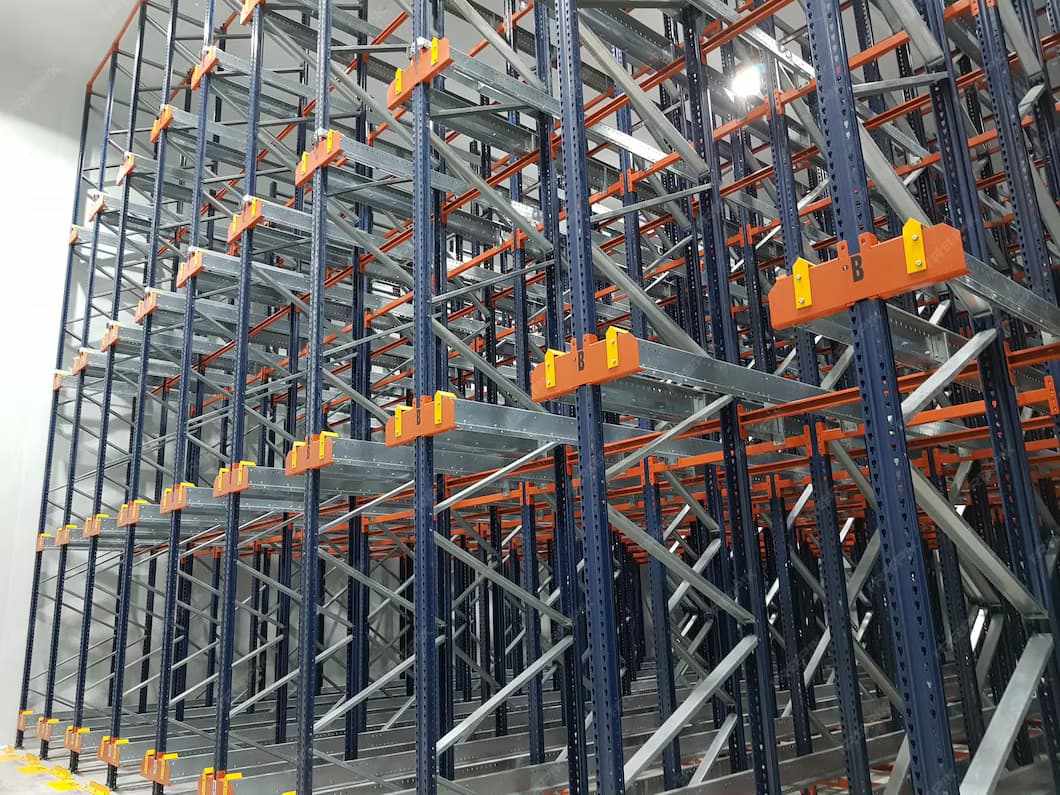

Pallet live racking is a dynamic storage system that uses gravity-driven roller tracks to move pallets from the loading side to the retrieval side. Pallets are placed on inclined rollers, and gravity moves them forward as the front pallet is removed. This design creates a continuous flow of goods and ensures that the first pallet loaded is the first pallet picked.

Unlike static racking, pallet live racking maintains product rotation automatically without requiring additional handling. This makes it particularly valuable for businesses that need to manage date-sensitive products efficiently.

How It Works

Operators load pallets at the higher end of the rack structure. As each pallet is placed, it slides gently along the rollers toward the picking face. When a pallet is removed, the one behind it moves forward, ensuring smooth replenishment. This flow reduces handling time and maintains consistent stock rotation.

Key Benefits of Pallet Live Racking

Ensures FIFO Inventory Control

One of the greatest advantages of pallet live racking is its support for first in, first out inventory management. This system automatically rotates stock, which helps businesses prevent spoilage, maintain freshness, and comply with strict product management standards.

Maximizes Storage Density

By minimizing aisle space and allowing multiple pallets to be stored in depth, pallet live racking makes efficient use of available warehouse space. Compared to selective racking, it can store significantly more goods in the same footprint.

Improves Efficiency

Because pallets automatically move forward as others are removed, operators spend less time searching or rearranging goods. This streamlines loading and picking processes, reducing overall handling time.

Reduces Product Damage

Since pallets flow smoothly on rollers, there is less need for forklifts to enter rack structures. This minimizes collisions and decreases the chances of product damage or structural wear.

Cuts Operational Costs

By improving space utilization and efficiency, pallet live racking reduces the need for larger facilities or costly expansions. Lower handling requirements also help cut labor costs and energy consumption.

Enhances Workplace Safety

The system is designed to minimize forklift movements inside rack structures, which reduces accident risks. Organized lanes and controlled pallet flow create a safer working environment.

Applications Across Industries

Food and Beverage

This industry relies heavily on strict inventory rotation to maintain product quality. Pallet live racking is ideal for storing packaged food, beverages, and other perishable goods that must follow FIFO rules.

Pharmaceuticals

In pharmaceutical warehouses, accurate stock control is vital. Pallet live racking ensures proper product turnover, reduces errors, and supports compliance with health and safety standards.

Cold Storage

Cold storage warehouses benefit from high-density systems that reduce cooling costs. Pallet live racking provides both compact storage and FIFO management for frozen or chilled goods.

Manufacturing

Manufacturers use pallet live racking to store raw materials and finished products efficiently. The system supports smooth inventory flow, which helps maintain production schedules.

Retail Distribution

Retailers with fast-moving consumer goods find pallet live racking valuable for handling large volumes of stock while ensuring timely rotation of items.

Important Considerations Before Installation

Product Type

Pallet live racking works best for uniform, palletized goods with consistent dimensions. Businesses storing irregular or oversized products may need alternative solutions.

Load Capacity

Each roller track is designed to handle specific load weights. Understanding the weight of stored goods is essential to ensure safety and prevent equipment strain.

Forklift Requirements

While forklifts do not need to enter the racking system, they must be able to place and retrieve pallets at the loading and picking faces efficiently. Compatibility between forklifts and rack design is key.

Maintenance Needs

Regular inspections are necessary to ensure rollers and braking systems function smoothly. Pallet damage or debris on the tracks can affect flow, so ongoing maintenance should be part of warehouse routines.

Safety Measures

Guardrails, safety stops, and proper training for operators should be in place to ensure safe use of the system. This helps avoid overloading or improper handling of pallets.

Best Practices for Effective Use

Strategic Slotting

Assigning products based on demand and turnover ensures efficient picking. Fast-moving items should be placed in easily accessible lanes, while slower-moving items can be positioned elsewhere.

Proper Training

Operators should be trained on how to load and retrieve pallets correctly. Proper handling prevents system disruptions and reduces risks of accidents.

Regular Inspections

Roller tracks, braking systems, and structural components should be checked routinely. Early detection of wear or misalignment helps maintain system reliability.

Integrating with Warehouse Management Systems

Pairing pallet live racking with digital inventory management provides real-time tracking and improves overall warehouse performance. This integration supports better decision-making and ensures accurate stock control.

Planning for Growth

When installing pallet live racking, it is important to design the system with future needs in mind. Scalable layouts allow for adjustments as business demands change.

Why Pallet Live Racking Is a Smart Investment

Pallet live racking combines the benefits of space optimization, FIFO compliance, and improved efficiency. It is a smart investment for businesses that deal with high volumes of stock requiring reliable rotation. By reducing costs, enhancing safety, and improving workflow, it contributes to long-term warehouse productivity and profitability.

Conclusion

Pallet live racking is more than just a storage solution. It is a strategic approach that ensures effective inventory rotation, maximizes space, and streamlines operations. From food and beverage to pharmaceuticals and cold storage, this system has proven its value in multiple industries. For businesses looking to optimize warehouse performance while maintaining strict inventory control, pallet live racking provides a practical and efficient answer.

For expert guidance and tailored solutions in implementing pallet live racking, Dalvie Systems is ready to help. Take the next step toward a more efficient warehouse with Dalvie Systems and experience the benefits of smarter storage today.

Write a comment ...