In the bustling environment of warehouses and distribution centers, the safety and efficiency of operations hinge significantly on the integrity of storage systems. Among these, racking systems play a critical role in organizing and storing inventory. However, like any other equipment, these systems require regular checks to ensure they remain safe and functional. This leads us to the crucial question: how often should you conduct a racking inspection? This article explores the importance of regular inspections, the factors influencing the frequency of those inspections, and the best practices to ensure a thorough evaluation.

The Importance of Racking Inspections

Racking inspections are essential for maintaining safety and compliance in a warehouse. Mishaps resulting from racking failures can lead to accidents, injuries, and significant financial losses. Conducting regular inspections helps identify potential hazards such as structural damage, wear and tear, and improper usage of the racking system. These inspections not only protect the workforce but also safeguard the inventory stored within the racks.

In addition to enhancing safety, routine inspections contribute to operational efficiency. An undetected racking issue can disrupt workflow, leading to delays in order fulfillment and increased downtime. By ensuring that racking systems are in optimal condition, businesses can maintain smooth operations and meet customer demands consistently. Regular inspections also help businesses comply with industry regulations and standards, avoiding potential fines and legal issues.

Factors Influencing Inspection Frequency

The frequency of racking inspections is not a one-size-fits-all approach. Several factors influence how often these inspections should be conducted:

1. Type of Racking System

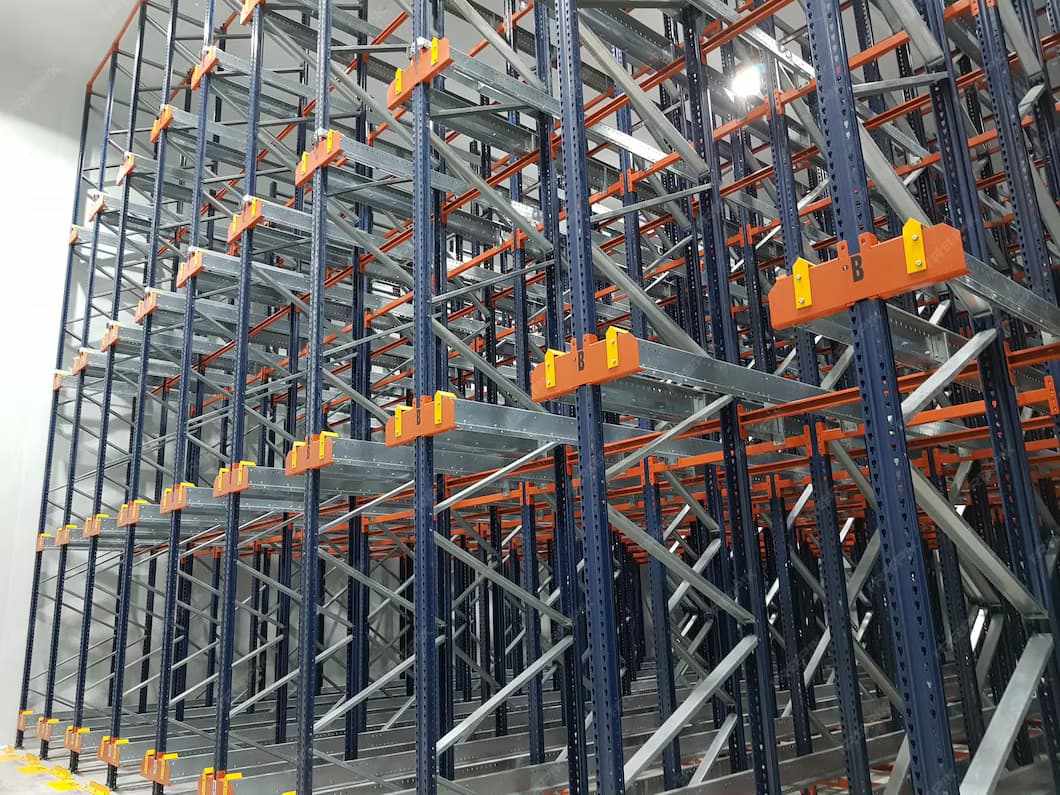

Different racking systems have varying requirements for inspections. For instance, selective racking systems may require more frequent checks compared to drive-in or push-back systems, which are often more complex and can be prone to specific types of damage. Understanding the unique characteristics of each racking system will help determine the appropriate inspection schedule.

2. Warehouse Activity Level

The intensity of warehouse operations plays a significant role in determining inspection frequency. High-traffic areas where forklifts and other equipment are in constant use may experience more wear and tear. Consequently, racking systems in these environments may need to be inspected more often to identify any potential issues before they escalate.

3. Load Capacity and Configuration

The weight and configuration of the loads stored on the racking system are critical factors. Overloading racks can lead to structural failure, making it essential to conduct inspections more frequently in environments where heavy or unstable loads are stored. Additionally, if the configuration of the racking system changes (e.g., adding new levels or modifying existing ones), it is vital to conduct an inspection to ensure the system’s integrity.

4. Environmental Conditions

Environmental factors can also impact the integrity of racking systems. Warehouses exposed to extreme temperatures, humidity, or corrosive materials may require more frequent inspections. Regular evaluations help detect any damage caused by environmental conditions, ensuring the safety and longevity of the racking system.

5. Regulatory Requirements

Certain industries may have specific regulations governing the frequency of racking inspections. For instance, the Occupational Safety and Health Administration (OSHA) and the American National Standards Institute (ANSI) provide guidelines regarding the inspection and maintenance of racking systems. Familiarizing oneself with these regulations is crucial for ensuring compliance and determining how often inspections should be conducted.

Recommended Inspection Frequency

While the frequency of racking inspections can vary based on the factors mentioned above, general guidelines can help warehouse managers establish a suitable schedule. Here are the recommended inspection frequencies based on industry standards and best practices:

1. Daily Visual Inspections

Warehouse personnel should conduct daily visual inspections of the racking systems as part of their routine. These informal checks involve looking for any obvious signs of damage, misalignment, or overloading. Documenting any findings is essential for tracking issues and addressing them promptly.

2. Monthly Detailed Inspections

A more comprehensive inspection should be performed monthly by trained staff or safety officers. This inspection focuses on identifying structural issues, checking for signs of corrosion, and verifying that the racking systems are in compliance with load specifications. During these inspections, it is crucial to assess the condition of safety features, such as guardrails and safety straps.

3. Annual Professional Inspections

In addition to regular in-house inspections, it is advisable to engage a qualified third-party professional to conduct an annual inspection of the racking systems. These experts are equipped to identify potential hazards that may go unnoticed by untrained personnel. Their insights can be invaluable for ensuring compliance with safety standards and regulations.

Best Practices for Racking Inspections

To maximize the effectiveness of racking inspections, businesses should adopt several best practices:

1. Establish a Clear Inspection Schedule

Creating a well-defined inspection schedule based on the factors discussed earlier will help ensure that inspections are conducted consistently. This schedule should be communicated to all relevant staff members and integrated into the overall safety management plan.

2. Train Staff on Inspection Protocols

Training warehouse staff on how to conduct effective inspections is critical. Employees should be knowledgeable about the common signs of racking issues and understand how to carry out visual checks. Regular training sessions can help reinforce the importance of inspections and ensure that safety remains a top priority.

3. Document Findings and Actions Taken

Thorough documentation of inspection findings is essential for tracking the condition of racking systems over time. Maintaining records of inspections, including any issues identified and corrective actions taken, can provide valuable insights into trends and help prioritize maintenance efforts.

4. Encourage a Culture of Safety

Cultivating a culture of safety within the warehouse is vital for promoting proactive racking inspections. Encouraging employees to report any concerns or observations related to racking systems can help create an environment where safety is prioritized, leading to fewer accidents and improved compliance.

Conclusion

In conclusion, conducting regular racking inspections is a critical aspect of maintaining a safe and efficient warehouse environment. The frequency of these inspections should be determined based on various factors, including the type of racking system, warehouse activity level, load capacity, and environmental conditions. By adhering to recommended inspection schedules and best practices, businesses can protect their workforce, safeguard their inventory, and ensure compliance with safety regulations.

For those looking to enhance their warehouse safety and efficiency, Dalvie Systems is ready to provide expert guidance tailored to your needs. Don’t wait for an issue to arise—contact Dalvie Systems today to discover how you can implement effective racking inspection practices and ensure the long-term success of your operations!

Write a comment ...