Pallet racking is one of the most effective solutions for maximizing warehouse storage space and improving operational efficiency. However, the benefits of a racking system can only be fully realized if it is installed correctly. Pallet rack installation is a detailed process that requires careful planning, precise execution, and a strong focus on safety. This guide provides a comprehensive overview of how to approach pallet rack installation in warehouses, from preparation and planning to execution and maintenance.

Understanding Pallet Rack Installation

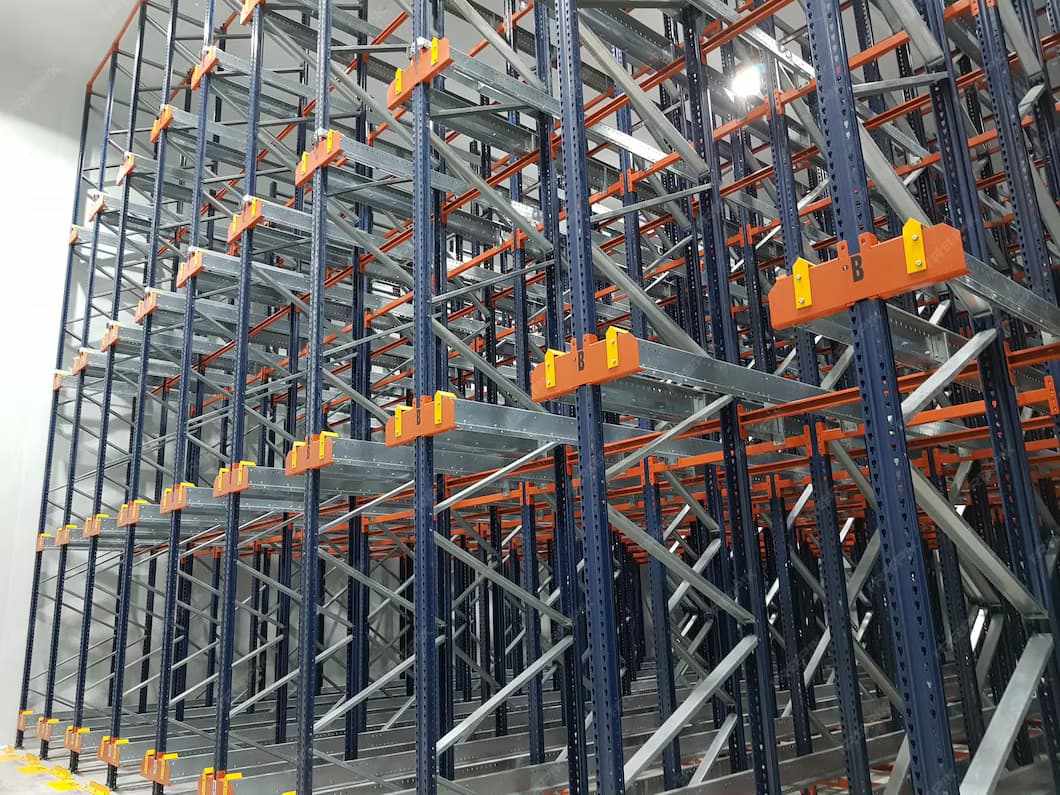

Pallet rack installation involves assembling and securing a structured storage system designed to hold palletized goods. These systems are commonly used in warehouses, distribution centers, and industrial facilities where efficient use of vertical space is crucial. Proper installation ensures that the racking system is safe, durable, and capable of supporting the intended load capacity.

Why Proper Installation Matters

Correct installation is not just about functionality. It plays a direct role in workplace safety, reducing the risk of accidents caused by collapsing racks or uneven load distribution. Furthermore, it ensures compliance with safety regulations and industry standards. A poorly installed racking system can lead to frequent repairs, unnecessary downtime, and increased costs over time.

Preparing for Pallet Rack Installation

Preparation is a critical phase of any pallet rack installation project. A well-prepared warehouse layout and a clear installation plan help avoid costly mistakes and delays.

Assessing Warehouse Needs

Before beginning the installation, it is important to evaluate the warehouse’s storage requirements. Factors such as the types of products stored, load capacities, aisle width, and material handling equipment must be considered. For example, a facility handling bulk items may require a different racking configuration than one storing small, lightweight goods.

Planning the Layout

Designing an efficient warehouse layout is key to maximizing storage capacity while maintaining smooth traffic flow. The installation plan should consider aisle spacing for forklifts, fire safety regulations, and access to emergency exits. Optimal placement of racks also allows for easier picking and replenishment, which directly impacts productivity.

Gathering Materials and Tools

Pallet rack installation requires specific components such as uprights, beams, braces, safety clips, and baseplates. Tools such as drills, levelers, wrenches, and safety gear must also be prepared in advance. Having everything ready before starting ensures a smooth installation process without unnecessary interruptions.

Step-by-Step Process of Pallet Rack Installation

A structured step-by-step approach helps achieve a safe and efficient pallet rack installation.

Step 1: Marking the Layout

The first step is marking the warehouse floor to define where each rack will be positioned. This ensures correct spacing between rows and aisles. Using chalk lines or laser markers helps maintain accuracy.

Step 2: Installing Uprights

Upright frames form the vertical structure of pallet racks. These must be placed on baseplates and securely anchored to the floor. Ensuring that each upright is level and properly aligned is essential to maintaining structural integrity.

Step 3: Adding Beams and Braces

Once the uprights are secured, horizontal beams and braces are installed. These components connect the uprights and provide support for pallets. Safety clips or locking pins should be used to secure beams in place, preventing accidental dislodgement.

Step 4: Checking Level and Alignment

During installation, frequent checks should be made to confirm that racks are level and aligned. Even minor misalignments can compromise the stability of the system and lead to uneven load distribution.

Step 5: Installing Safety Accessories

To enhance safety, accessories such as frame protectors, column guards, and wire decking can be installed. These features help prevent damage from forklifts and ensure that pallets are stored securely.

Step 6: Load Testing and Final Inspection

Before using the racking system, it is crucial to conduct load testing to verify that it can handle the intended weight capacity. A final inspection should also confirm that all components are properly installed, secured, and compliant with safety regulations.

Safety Considerations in Pallet Rack Installation

Safety should always be the top priority during installation. Failure to follow proper safety practices can result in severe accidents.

Following Manufacturer Guidelines

Every racking system comes with specific installation instructions provided by the manufacturer. Following these guidelines ensures that the system is assembled according to its design specifications.

Using Proper Anchoring

Anchoring is one of the most important steps in pallet rack installation. Anchors secure the uprights to the warehouse floor, preventing racks from shifting under heavy loads or forklift impact. Incorrect or weak anchoring can compromise the entire system.

Personal Protective Equipment (PPE)

Installers should always wear appropriate PPE, including hard hats, gloves, steel-toed boots, and high-visibility clothing. This reduces the risk of injuries during the installation process.

Load Capacity Compliance

Exceeding the rated load capacity of a racking system is one of the leading causes of warehouse accidents. Clear signage indicating load limits should be displayed on each rack, and staff should be trained to adhere to these limits.

Common Challenges in Pallet Rack Installation

Even with careful planning, pallet rack installation can present challenges.

Uneven Flooring

Many warehouses have floors that are not perfectly level. This can make it difficult to align racks correctly. Using shims can help adjust for uneven surfaces.

Space Constraints

Limited space can make installation more complex, particularly in facilities with narrow aisles. Careful layout planning helps overcome this challenge.

Handling Heavy Components

Uprights and beams are often large and heavy. Safe handling practices and, where necessary, the use of lifting equipment are essential to prevent injuries.

Post-Installation Best Practices

Once the pallet racking system is installed, ongoing practices ensure its long-term performance and safety.

Regular Inspections

Routine inspections help identify potential issues such as damaged beams, loose bolts, or misaligned uprights. Regular checks ensure that the system remains safe and compliant.

Staff Training

Employees should be trained not only in safe loading and unloading practices but also in recognizing signs of rack damage. Proper training reduces the likelihood of accidents.

Maintenance and Repairs

Any damage to the racking system should be addressed immediately. Neglecting repairs can lead to structural failure and costly downtime.

Adapting to Future Needs

Warehouses often experience changes in product types, volumes, or workflows. Regularly reviewing and adjusting the racking configuration helps ensure that the system continues to meet operational demands.

Conclusion

Pallet rack installation is a vital part of warehouse optimization. When carried out with careful planning, precision, and strict adherence to safety practices, it creates a reliable and efficient storage solution. From assessing warehouse needs and planning layouts to executing the installation and ensuring ongoing maintenance, every step plays a crucial role in the success of the system. A well-installed pallet racking system not only maximizes storage capacity but also enhances safety, productivity, and long-term cost efficiency.

Write a comment ...